In the landscape of industrial processes, innovation continues to reshape traditional methodologies, bringing forth more efficient, sustainable, and cost-effective solutions. One such revolutionary technology is the pulp dewatering screw press, which has garnered attention for its transformative impact on solid-liquid separation. In this article, we delve into the inner workings, benefits, environmental impact, and introduce Tianzhong Machinery as a prominent supplier of screw press dewatering machines from China.

Work Mechanism of Dewatering Screw Press

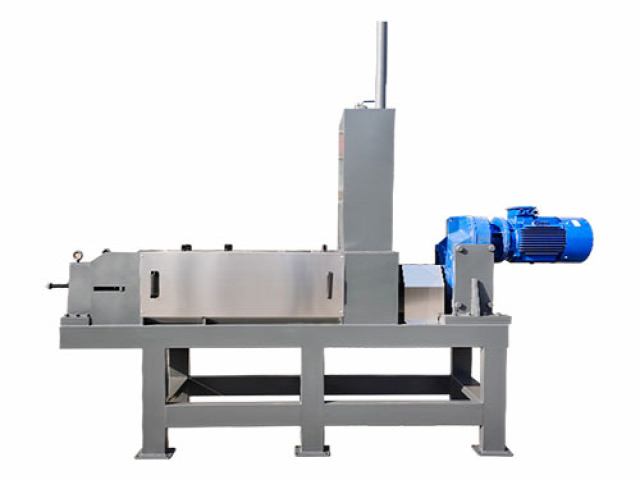

The pulp dewatering screw press operates as a marvel of engineering ingenuity. At its core lies a simple yet effective mechanism that facilitates the separation of liquids from pulpy materials. The machine features a cylindrical drum and a helical screw within it. As the pulpy mixture enters the press, the helical screw's rotational motion propels the material forward while applying pressure. This pressure initiates the dewatering process by squeezing out liquids from the pulpy mass. The extracted liquids seep through gaps in the screw and drum, leaving behind a drier and more concentrated solid residue.

Benefits and Advantages

The adoption of a pulp dewatering screw press, such as those offered by Tianzhong Machinery, brings forth a plethora of benefits that resonate across various industries:

1. **Enhanced Efficiency:** Traditional dewatering methods can be time-consuming and energy-intensive. The screw press accelerates this process, reducing energy consumption and boosting throughput.

2. **Customizable:** The flexibility of screw press technology allows operators to adjust parameters such as rotational speed and screw pitch. This customization ensures optimal dewatering performance for a wide range of pulpy materials.

3. **Reduced Environmental Footprint:** By efficiently separating liquids from solids, the screw press diminishes waste volume, leading to reduced disposal costs and a smaller environmental impact.

4. **Resource Recovery:** Extracted liquids can be repurposed, potentially serving as valuable byproducts or contributing to other production processes.

5. **Minimal Maintenance:** Pulp dewatering screw presses are known for their robust design and low maintenance requirements, resulting in improved operational efficiency.

Environmental Impact

The environmental implications of the pulp dewatering screw press are noteworthy. As industries around the globe strive to adopt greener practices, this technology aligns well with sustainability objectives:

1. **Waste Reduction:** The efficient dewatering process significantly reduces the volume of waste requiring disposal, aiding in minimizing landfill usage and lowering transportation costs.

2. **Energy Efficiency:** The reduced energy consumption associated with screw press dewatering supports a greener approach to industrial operations.

3. **Resource Conservation:** By maximizing the extraction of liquids from pulpy materials, the technology contributes to the conservation of valuable resources and raw materials.

Supplier Information: Tianzhong Machinery

Tianzhong Machinery stands as a distinguished leader in the field of screw press dewatering machines. Based in China, the company has established itself as a reliable and innovative provider of solutions for solid-liquid separation challenges. With a commitment to quality and technological advancement, Tianzhong Machinery's offerings encompass a wide range of industries, including pulp and paper, food processing, and more.

The company's extensive portfolio of dewatering screw presses reflects its dedication to meeting diverse customer needs. By combining cutting-edge engineering with a customer-centric approach, Tianzhong Machinery has earned a reputation for delivering high-performance machines that drive efficiency and sustainability.

Conclusion

The dewatering screw press, exemplified by the offerings of Tianzhong Machinery, embodies the convergence of innovation and sustainable industrial practices. Its ingenious work mechanism, coupled with the multifaceted benefits it offers, has positioned it as an essential solution for various sectors. As global industries continue to prioritize resource efficiency and environmental responsibility, the pulp dewatering screw press, with its remarkable impact on solid-liquid separation, remains at the forefront of transformative technologies.